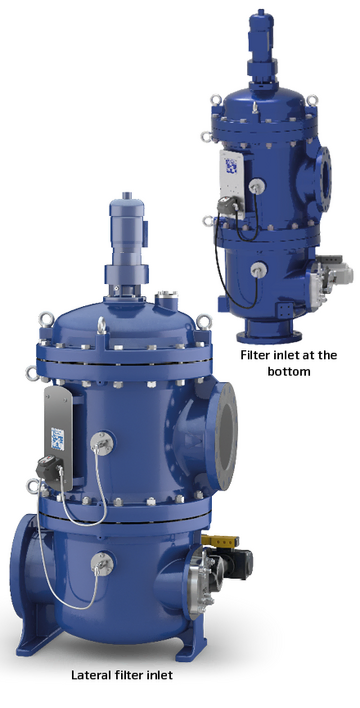

Automatic Backwash Filter

Self-cleaning filter system with automatic backwash capability, designed for continuous operation and optimal process efficiency.

Key Features

- Continuous operation without interruption

- Self-cleaning mechanism

- Can be used as connected filters

- Suitable for hard-to-reach locations

- Reduced maintenance requirements

Applications

Water Treatment

Filtration of process water, cooling water, and wastewater

Industrial Process

Protection of process equipment and systems

Cooling Systems

Filtration of cooling water in HVAC systems

Oil & Gas

Filtration of process fluids and equipment protection

Technical Specifications

Connection Sizes

DN 50 to DN 1000

Filtration Rating

10 µm - 5 mm

Temperature Range

-20°C to +180°C

Pressure Range

Up to 40 bar

Design Options

Vertical / Horizontal

Material Options

Carbon Steel / Stainless Steel

How It Works

Filtration Phase

During normal operation, the filter continuously removes particles from the process fluid. The filter element captures contaminants while maintaining optimal flow rates. The differential pressure is constantly monitored to determine when cleaning is needed.

Backwashing Phase

When the differential pressure reaches the preset limit, the automatic backwashing process begins. The system reverses the flow direction, using filtered process fluid to clean the filter element. This process is fully automatic and requires no manual intervention.

Recovery Phase

After backwashing, the system returns to normal filtration mode. The cleaned filter element is ready for the next cycle. The entire process is continuous, ensuring uninterrupted operation while maintaining optimal filtration efficiency.

Ready to Optimize Your Filtration System?

Experience the efficiency of our automatic backwash filters. Our experts can help you:

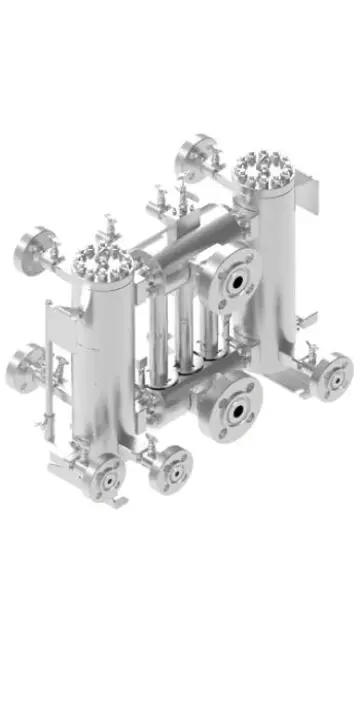

Duplex Filter

Dual-chamber filter system for continuous operation with automatic switching capability.

Key Features

- Continuous operation with dual filter housings

- Seamless switching between filter units

- Double Block and Bleed technology for safety

- Easy maintenance and cleaning

- Wide range of filter elements available

Applications

Industrial Processes

Continuous filtration for critical industrial processes requiring uninterrupted operation

Oil & Gas Systems

Protection of equipment in fuel oil and lube oil systems

Compressor Protection

Filtration of gas and oil for compressor and turbine protection

Water Systems

Industrial water filtration with continuous operation capability

Technical Specifications

Connection Sizes

DN 20 to DN 1000

Filtration Rating

10 µm - 5 mm

Temperature Range

-20°C to +180°C

Pressure Range

Up to 40 bar

Design Options

Vertical / Horizontal

Material Options

Carbon Steel / Stainless Steel

How It Works

Filtration Phase

One filter unit operates while the other remains in reserve. The clogging indicator monitors pressure loss and signals when maintenance is needed. The system maintains continuous flow while one chamber is in operation.

Switch-over Process

When maintenance is required, the system seamlessly switches to the clean filter chamber. The switchover mechanism ensures a smooth transition without pressure surges or process interruption. The dirty filter chamber is then isolated for maintenance.

Cleaning Phase

After depressurization, the filter element can be safely removed for cleaning. The system supports various cleaning methods, including standard cleaning procedures or optional ultrasonic cleaning devices. Once cleaned, the filter is ready for the next cycle.

Ready to Ensure Continuous Operation?

Discover the reliability of our duplex filters. Our specialists can help you:

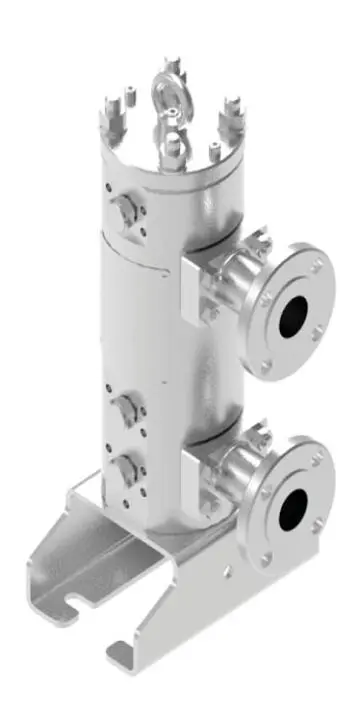

Simplex Filters

Foundation of filtration with efficient and compact design for streamlined operations

Key Features

- Compact and efficient design

- Easy maintenance and cleaning

- Reliable filtration performance

- Versatile filter element options

- Space-saving installation

Applications

Industrial Processes

Protection of system components against contamination in various industrial applications

Gas Filtration

Effective particle filtering and separation of solids and aerosols from gases

Liquid Filtration

Versatile solutions for both low and high-pressure liquid filtration systems

Equipment Protection

Protection of critical equipment and systems from contamination

Technical Specifications

Connection Sizes

DN 20 to DN 1000

Filtration Rating

10 µm - 5 mm

Temperature Range

-20°C to +180°C

Pressure Range

Up to 40 bar

Design Options

Vertical / Horizontal

Material Options

Carbon Steel / Stainless Steel

How It Works

Filtration Process

The process fluid flows through the filter element, which captures contaminants while allowing clean fluid to pass through. The filter element can be customized based on specific filtration requirements.

Maintenance Process

When cleaning is required, the system is depressurized and the housing cover is removed. The filter element can be easily accessed for cleaning or replacement, ensuring minimal downtime.

Cleaning Methods

The filter element can be cleaned using various methods including rinsing with cleaning fluid, compressed air, or optional ultrasonic cleaning devices, ensuring thorough removal of contaminants.

Ready to Streamline Your Filtration?

Experience the efficiency of our simplex filters. Our team can help you:

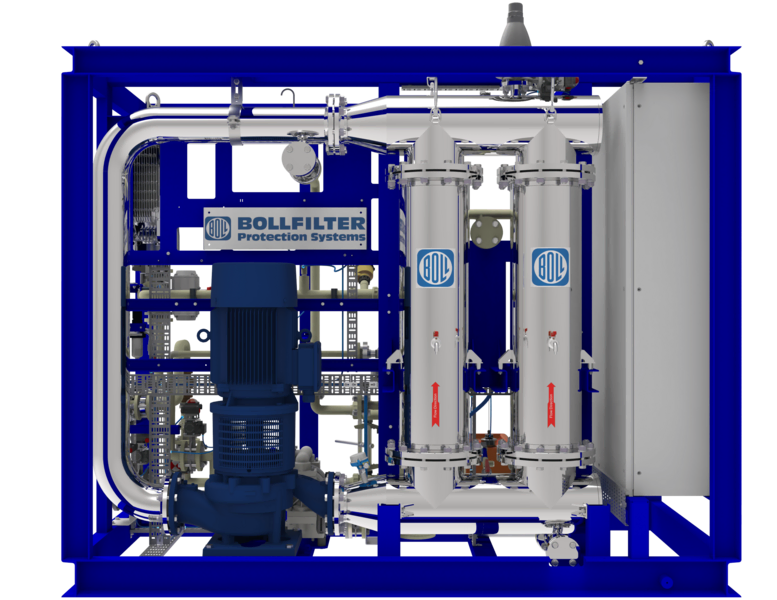

Fine Filter Unit

Ultra filtration systems operating at the molecular level for precise separation and purification

Key Features

- Molecular level filtration (1-100 nm)

- Semi-permeable membrane technology

- Selective separation of particles and solutes

- High-precision filtration control

- Protection of sensitive processes

Applications

Process Water Treatment

Ultra filtration for process water purification and treatment systems

Industrial Processes

Precise separation in manufacturing and processing applications

Chemical Processing

Separation of molecules and particles in chemical applications

Water Recycling

Advanced filtration for water reuse and recycling systems

Technical Specifications

Connection Sizes

DN 20 to DN 1000

Filtration Rating

1 to 100 nanometers

Temperature Range

-20°C to +180°C

Pressure Range

Up to 40 bar

Design Options

Vertical / Horizontal

Material Options

Carbon Steel / Stainless Steel

How It Works

Molecular Separation

The semi-permeable membrane allows water, dissolved ions, and small molecules to pass through while retaining larger molecules, colloids, and suspended solids. This precise separation occurs at the molecular level.

Selective Filtration

The membrane's pore size (1-100 nm) determines which particles are filtered out. This selective process ensures that only desired components pass through while unwanted particles are retained.

Process Control

The system maintains precise control over the filtration process, ensuring consistent performance and quality of the filtered output. Parameters can be adjusted to meet specific application requirements.

Need Help Selecting the Right Filter?

Our technical team can assist you in choosing the perfect fine filter unit for your specific requirements.

Contact Our Experts